Why SPYDERCRANE

The SPYDERCRANE Brand Advantage for Your Jobsite

People often ask what makes SPYDERCRANE mini crawler cranes so special? The answer isn’t as simple as it seems. To really dive into the SPYDERCRANE mini crane we first must look at the features that make the SPYDERCRANE brand unique.

Patented Overturn Protection System

The UNIC SPYDERCRANE Overturn Protection System is a patented UNIC exclusive safety system that is included on the SPYDERCRANE URW090 Series, URW200 Series, and some URW300 Series models.

The UNIC SPYDERCRANE Overturn Protection System is a patented UNIC exclusive safety system that is included on the SPYDERCRANE URW090 Series, URW200 Series, and some URW300 Series models.

The Overturn Protection System is comprised of an on-board computer system that continually measures ground pressure on each outrigger through an incorporated “load cell” in each outrigger. If during a lift, one outrigger starts to lose ground pressure and is nearing the safe operating limits of the crane, an alarm will sound and the SPYDERCRANE mini-crawler crane will start to slow the crane functions. If two outriggers start to loose ground pressure, the mini crane will automatically stop all functions that would put the crane closer to an unsafe configuration. With the alarms sounding and the crane stopped, the operator will now be able to maneuver the crane back into a favorable operating position to continue the lift.

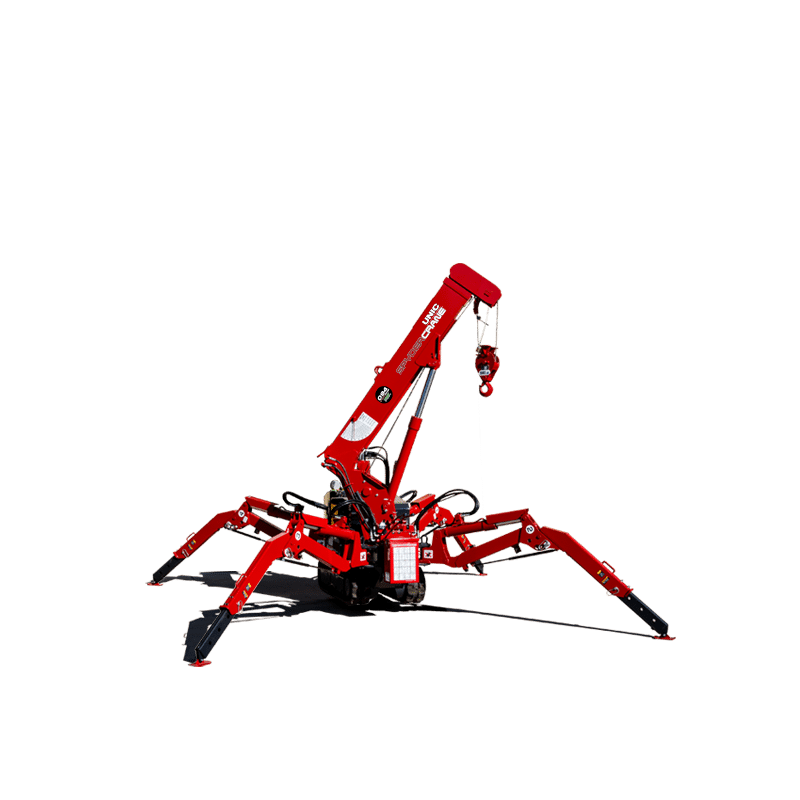

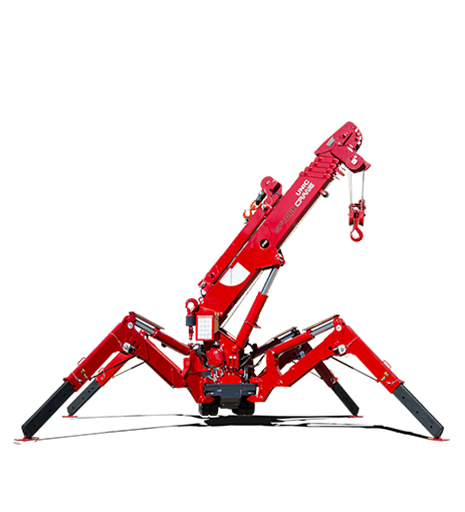

Variable Geometry Outriggers

Variable Geometry Outriggers allow for lifts in tight spaces. A standard feature on the 090 and 200 Series SPYDERCRANE models, by offering numerous locking positions on the outrigger swing, knee, and inner box joints, the SPYDERCRANE mini crane can set up around an obstacle, on a catwalk, or in a machinery room in very limited spaces.

Variable Geometry Outriggers allow for lifts in tight spaces. A standard feature on the 090 and 200 Series SPYDERCRANE models, by offering numerous locking positions on the outrigger swing, knee, and inner box joints, the SPYDERCRANE mini crane can set up around an obstacle, on a catwalk, or in a machinery room in very limited spaces.

Remote Control and Pressure Sensitive Controls

Unlike most cranes on the market, SPYDERCRANE mini cranes offer pressure sensitive controls that speed or slow crane functions based on the amount of pressure input by the operator. Most SPYDERCRANE mini cranes are also equipped with a wireless remote control so an operator can position themselves into the best vantage point for their lift. Combined, these features make SPYDERCRANE branded mini cranes some of the most operator friendly mini cranes on the market.

Unlike most cranes on the market, SPYDERCRANE mini cranes offer pressure sensitive controls that speed or slow crane functions based on the amount of pressure input by the operator. Most SPYDERCRANE mini cranes are also equipped with a wireless remote control so an operator can position themselves into the best vantage point for their lift. Combined, these features make SPYDERCRANE branded mini cranes some of the most operator friendly mini cranes on the market.

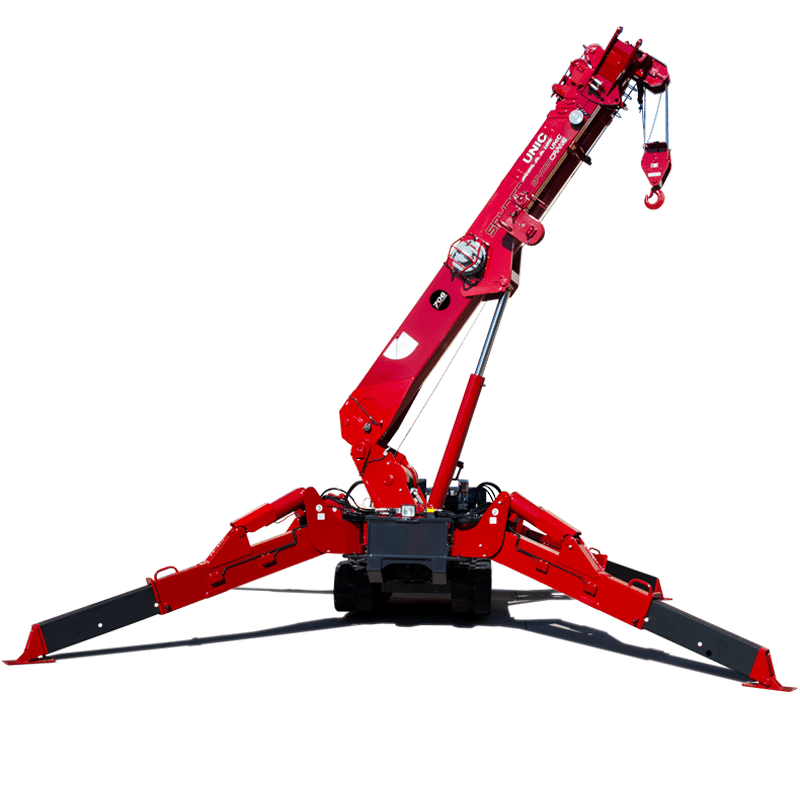

Superior Materials and Construction

The SPYDERCRANE mini crane is designed with a hexagonal keeled boom instead of a square boom, adding boom strength and reducing boom sway. Constructed using steel that is rated at 140,000 – 160,000 yield (psi), the high tinsel-high yield steel is thinner and lighter than most conventional booms, but by design, sturdier. This leads to a lighter crane that can lift more.

The SPYDERCRANE mini crane is designed with a hexagonal keeled boom instead of a square boom, adding boom strength and reducing boom sway. Constructed using steel that is rated at 140,000 – 160,000 yield (psi), the high tinsel-high yield steel is thinner and lighter than most conventional booms, but by design, sturdier. This leads to a lighter crane that can lift more.

The superior materials and design of the SPYDERCRANE products speak to attention to detail and quality that go into every SPYDERCRANE mini crawler crane.

Narrow Track Width and Low Center of Gravity

SPYDERCRANE mini cranes can travel through standard size single or double doors depending on the model. The SPYDERCRANE mini crane was thoughtfully designed with a low center of gravity to stabilize the mini crane when traveling and during crane operations. Due to this low center of gravity and increased stability, SPYDERCRANE mini cranes offer some of the narrowest mini cranes in their class.

SPYDERCRANE mini cranes can travel through standard size single or double doors depending on the model. The SPYDERCRANE mini crane was thoughtfully designed with a low center of gravity to stabilize the mini crane when traveling and during crane operations. Due to this low center of gravity and increased stability, SPYDERCRANE mini cranes offer some of the narrowest mini cranes in their class.

SPYDERCRANE Mini Cranes

Pick & Carry Series

Max Capacity: 5,070 lbs

Boom Length: 18.1 ft

094 Series

Max Capacity: 1,900 lbs

Boom Length: 18.0 ft

200 Series

Max Capacity: 6,450 lbs

Boom Length: 28.4 ft

300 Series

Max Capacity: 6,680 lbs

Boom Length: 47.8 ft

500 Series

Max Capacity: 8,920 lbs

Boom Length: 59.1 ft

700 Series

Max Capacity: 13,300 lbs

Boom Length: 81.0 ft

1006 Series

Max Capacity: 20,000 lbs

Boom Length: 78.0 ft

Frequently Asked Questions about the SPYDERCRANE Mini Crane

A “SPYDERCRANE “ mini-crawler is a mini-crane that has been designed and built for working in low access confined areas either indoors or outdoors. It is mounted on a dual track chassis with “spider-type” legs for its outriggers. The SPYDERCRANE mini crane will go where a conventional truck mounted crane or carry deck crane will not have access due to its size.

The UNIC mini-crane was designed, developed, and is manufactured by Furukawa UNIC, a Japanese company that has the largest distribution and production of hydraulic cranes in the world. Furukawa UNIC is the inventor and pioneer of the mini-crawler crane. Brought to North America and modified for the US and Canadian markets by Smiley Lifting Solutions, all SPYDERCRANE branded mini cranes get their start at Smiley Lifting Solutions in Phoenix, Arizona.

Furukawa UNIC is a Japanese company that has been producing hydraulic equipment since 1946. They are the largest manufacture of hydraulic cylinders and cranes worldwide. Furukawa UNIC is the largest manufacturer of truck mounted cranes and mini-crawlers.

The UNIC mini crane was first developed 30 years ago and has been widely used in the Asian market and European market for this time. It was first introduced into North America (United States and Canada) by Smiley Lifting Solutions.

With so many different sizes of cranes it can be hard figure out which one is right for you. Call us at 1-800-452-5011 to speak with one of our experienced staff to help you make the proper crane sizing decision for your job and location.

Depending on the size of the SPYDERCRANE mini crane there may be no special qualifications needed to operate the mini-crawler. Our support staff is only a phone call away if you have questions throughout your project. Users should always check local, regional, and federal regulations to ensure compliance.

Upon delivery of a SPYDERCRANE mini crane to your jobsite, our technicians will conduct a general familiarization of the machine. If additional formal training is required for your job site, SPYDERCRANE Qualified Operator Training is available. Contact us at 1-844-264-8994 or check out our training website at http://training.smileylifting.info.

Yes, our mini cranes are available to rent anywhere in North America. Please call us to find out our logistical capabilities.

UNIC SPYDERCRANE mini cranes are considered the safest cranes in the market because of the safety features we include as standard equipment. The standard safety features include: UNIC patented “Over-Turn Protection System”, LMI-Overload Protection, Winch Cable Over Winding Prevention Device, Minimum Wire Rope on Drum Prevention Device, Automatic Hook Stow System, Hook Safety Latch, Anti-two Block System, and an On-board Self-diagnostic Computer System, with Voice Messaging.

Overturn Protection System is a patented UNIC exclusive safety device that is included on the SPYDERCRANE 090 Series, 200 Series, and URW306(t) models. There is no other crane that can offer this state-of-the-art safety device. It is a far superior system compared to a common LMI System. The Overturn Protection interfaces with the on-board computer system and continually measures ground pressure on each outrigger, through a “load cell” on that is incorporated into each outrigger. When one outrigger starts to lose ground pressure, an alarm sounds and the mini-crawler will start to de-rate itself and slow the crane functions. When two outriggers start to loose ground pressure, the crane will stop all functions that would put the crane into an unsafe position. With the alarms sounding and the crane stopped, the operator will only be able to position the crane back to the safe mode. An LMI-overload system will not stop the motion of a crane when an outrigger is sinking into lose ground, but the UNIC Overturn Protection on the SPYDERCRANE mini crane will shut the crane down.

Yes. Depending on the SPYDERCRANE model you choose, you will have a choice of; battery 110V power, gasoline, propane, diesel, 220-480V single phase and 3 phase electric, or a combination of power such as gasoline/propane/220V electric all on one machine. The battery powered mini-crawlers will last up to 8 hours on a full charge and can be plugged into a common 110V wall outlet for operation and charging of the system.

Yes. All SPYDERCRANE mini cranes distributed in North America are built to meet current EPA standards and regulations.

All SPYDERCRANE models distributed in North America are manufactured to all current standards and regulations. This includes ASME B30.5 and CSA Z150 compliance standards, which applies to all mobile cranes. OSHA regulations require conformity to ASME B30.5.

Yes. All SPYDERCRANE mini cranes except the URW306(t) model are equipped with a wireless four-function radio-remote control system. The remote has an operating range of a 300 ft. radius. The system operates on a 15 channel frequency, which makes it impossible for any type of interference. Critical work environments such as Military aircraft facilities and Nuclear Power stations use this proven system without any interference with radar. This wireless remote control is standard on all SPYDERCRANE models.

Yes. Smiley Lifting Solutions has created a work basket designed specifically for the mini crane. Each basket is designed and manufactured to current North American standards and regulations. They are made of a lightweight chromalloy steel and easily attach to the boom tip of the mini-crawlers.

Yes. The SPYDERCRANE URW094 has a total of 62 possible outrigger positions and the rest of the 090 and 200 series cranes have a total of 52 possible outrigger positions. SPYDERCRANE mini-cranes are the only available cranes with this feature. This is possible because of the patented Overturn Protection system. Due to the fact that all other cranes are equipped with the limiting and un-advanced LMI-overload system, it is impossible for them to achieve this highly usable outrigger positioning feature. With the advanced outrigger positioning system, the SPYDERCRANE mini crane can set-up and operate in almost any confined work environment.

Are you thinking about renting a crane for your next project, but not sure that you’ll want to continue renting a crane over an extended period of time? Our Rent-to Purchase plan allows you rent the equipment that you need with the option to purchase it at a later date, using funds that have been paid in from the rental. Contact SPYDERCRANE today to see how we can tailor a rental package to fit your specific needs.

UNIC SPYDERCRANE Mini Cranes on the Jobsite

Innovative Windows & Glass

Installing Glass Using a SPYDERCRANE 200 Series & SPYDERWEB